3BHB009885R0031 What is the added functionality of the S-093S phase module?

Date: Oct 18, 2025 Views: 910

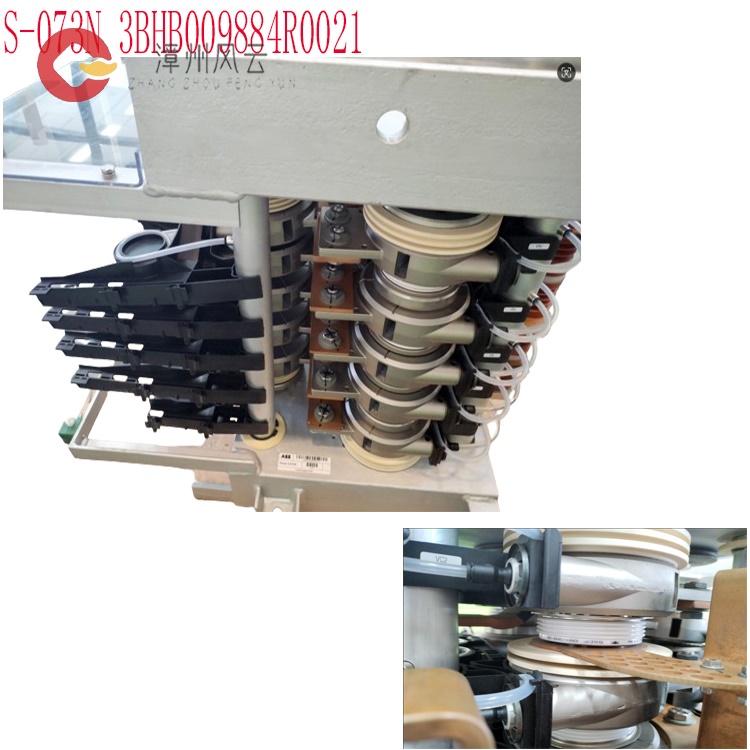

Hardware Installation and Physical Configuration

Modular Installation: The phase module 3BHB009885R0031 S-093S is installed in a standard 19-inch cabinet or DIN rail. Ensure the module is fully aligned with the rack slot and the mounting bracket is secure. The module body has an IP20 protection rating and requires a cabinet with higher protection (e.g., IP54).

Electrical Connections:

The input voltage range must match the system requirements (e.g., 6.0–6.9 kV) and redundant power modules must be configured. When connecting the output to a motor or load, ensure the correct phase sequence.

.jpg)

An external cooling system (air or water cooling) is required to ensure unobstructed heat dissipation to prevent dust accumulation that affects heat dissipation efficiency.

Grounding and Protection: Use equipotential single-point grounding, with lightning protection grounding separated from the system ground. Signal lines must be equipped with filters, and power and signal wiring must be separated to prevent electromagnetic interference.

Software Configuration and Parameter Settings

Programming Tools: Use ABB Control Builder M or Automation Builder software for parameter configuration and program development, supporting the IEC 61133-3 standard and CODESYS environment.

Core Parameter Settings:

Motor Parameters: Enter rated voltage, current, frequency, speed, power, etc. (e.g., a 6000kW motor must accurately match the nameplate data).

Control Mode: Select V/F control, vector control, or direct torque control (DTC) to adapt to different load conditions (e.g., the high dynamic requirements of rolling mills and wind turbines).

Dynamic Parameters: Set acceleration and deceleration times, overcurrent protection thresholds, undervoltage protection values, etc.; configure I/O channel mapping (e.g., digital input/output and analog input/output range calibration).

Advanced Features: Enable dynamic reactive power compensation, grid fault ride-through protection, and energy regeneration (brake energy is fed back to the grid, with an efficiency of up to 92%).

Phase Module 3BHB009885R0031 S-093S Communication Connection and System Integration

Protocol Selection: Supports industrial standard protocols such as Modbus TCP, PROFINET, Ethernet/IP, and OPC UA. Configure the IP address, subnet mask, gateway, and port number to ensure compatibility with host computers (such as PLCs and SCADA systems) or third-party devices (such as Siemens/Schneider equipment).

Data Interaction: Connect to HMI/SCADA systems via OPC UA or connect to domestic configuration software (such as KingView) via Modbus TCP. Configure register mapping (e.g., frequency settings correspond to register 40001).

Synchronization Verification: Use a network test tool (such as Wireshark) to check packet transmission to ensure correct protocol configuration; send test commands through DriveComposer software to verify communication stability.

Phase Module 3BHB009885R0031 S-093S Debugging and Optimization

No-load Test: Disconnect the load, start the inverter at 50Hz, listen for abnormal sounds, and perform an emergency stop test to verify basic functionality.

Load Test: Gradually increase the load, monitor output current, voltage, temperature, and other parameters, and adjust acceleration and deceleration times and PID parameters to optimize dynamic performance.

Fault Diagnosis: Use built-in self-diagnostic functions (such as fault code query and logging) to locate problems. Use the LED indicators (RUN/ERR) to determine operating status; a solid red light indicates a hardware fault.

Phase Module 3BHB009885R0031 S-093S Maintenance and Safety Specifications

Regular Maintenance: Check cooling system efficiency, electrical parameter fluctuations, and ground connection reliability; clean the heat sink and replace aging fans or thermal grease.

Safety Operation: Disconnect power before performing module replacement or maintenance. Avoid working with live power. Wear insulating protective equipment for high-voltage components and ensure that the ground resistance is ≤4Ω.

Compatibility Verification: When integrating with third-party devices, verify communication protocol compatibility (such as PROFIBUS DP master configuration). Firmware upgrades must be stored via eMMC to prevent program loss during power outages.

Phase Module 3BHB009885R0031 S-093S Installation and Configuration Key Points

Physical Installation:

Must be installed in a panel or cabinet meeting NEMA 12/13 or IP20/IP54 protection ratings, ensuring adequate ventilation (ambient temperature -25°C to +70°C).

The busbar design utilizes symmetrical flexible connectors with short paths to reduce stray inductance. External interfaces utilize rigid copper busbars with insulating fasteners.

Electrical Connections:

Inputs/outputs must be connected via an isolation transformer or directly to the grid, compatible with 6kV/10kV voltage levels.

Configuration must comply with ABB's official wiring specifications to avoid short circuits or module damage due to incorrect wiring (such as accidentally grounding the "N" line).

Software Configuration:

Parameters are set using ABB's dedicated tools (such as System 800xA), supporting dynamic response adjustment, fault diagnosis, and self-diagnosis.

Communication protocols and redundancy mechanisms (such as parallel redundancy and hot-swappable functionality) must be configured to ensure continuous system operation.

Special Scenarios

Multi-motor coordination: Connect multiple motors via a common DC bus to achieve energy recycling (such as feeding braking energy back to the grid), reducing energy consumption by over 15%.

Harsh Environments: For high-dust and high-corrosion environments such as mining and chemical industries, corrosion-resistant materials and coatings are used, and sealing design is enhanced. For offshore wind power plants, lightning protection and electromagnetic pulse protection devices are installed.

.jpg)

Maintenance and Troubleshooting

Common Problem Solutions:

Overcurrent/Short Circuit: Check the load conditions to confirm whether the module's rated current is exceeded; test the drive circuit using a dummy load.

Overheating: Check the cooling system (such as radiator cleanliness and silicone grease condition) and ensure adequate ventilation.

Communication Failures: Verify interface configuration and protocol compatibility, and troubleshoot network interference or hardware failures.

Repair Recommendations:

In the event of a module failure, contact ABB's official after-sales service or authorized service provider first to avoid secondary damage caused by unprofessional repairs.

Regularly check the condition of components such as varistors and capacitors, and replace aging components promptly.

Application Scenarios and Compatibility

Industrial Automation: Motor speed control, production line control, and conveyor synchronization.

New Energy: Wind turbine pitch control systems and solar tracking drives.

Rail Transit: Dynamic speed control and braking of subway/light rail traction motors.

Compatible Systems: ABB 800xA, AC 800M, and third-party PLCs (interface

protocol verification required).

Related product recommendations:

PM511V16 3BSE011181R1

PM511V08 3BSE011180R1

PM866K01 3BSE050198R1

PM633 3BSE008062R1

PM802F 3BDH000002R1

PM820-1 3BSE010797R1

PM825 3BSE010796R1

3BSE010800R1 PM825-1

3BSE093350R1 PM858-C

PM861AK01 3BSE018157R1

3BSE018105R1 PM861K01

3BSE018161R2 PM864AK01-eA

3BSE030193R1 PM865

PM864AK01 3BSE01816R1

3BSE031151R1 PM865K01

PM866-2 3BSE050201R1

3BSE081638R1 PM867K02

3BSE076355R1 PM867K01

More......

RELATED ARTICLE

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102