What role does the S-053M 3BHB012897R0003 phase module play in the ACS6000 system and PCS6000 system?

Date: Nov 15, 2025 Views: 38

Core Roles in the ACS6000 System

Motor Control Hub: As the physical carrier of Direct Torque Control (DTC) technology, it achieves instantaneous and precise control of motor torque and speed through high-precision phase detection and dynamic adjustment algorithms, avoiding starting current surges and adapting to high-dynamic load scenarios such as rolling mills and hoists.

Multi-Motor Cooperative Controller: Under a common DC bus architecture, it ensures energy feedback and load balance among multiple motors through phase synchronization. For example, in steel mill drives, the module coordinates the phases of multiple motors to eliminate rolling force fluctuations and improve steel precision.

Power Quality Guardian: Integrates overvoltage/undervoltage/overcurrent protection and fault diagnosis interfaces. Combined with a fuse-free design and arc protection, it ensures system safety within a power range of 3-36MW, while supporting V/F control, vector control, and other modes to adapt to asynchronous/synchronous motor requirements.

Dynamic Response Enhancer: Utilizing the module's built-in thyristor/IGCT power devices, it quickly adjusts the conduction angle to cope with sudden load changes, such as suppressing current surges during rolling mill startup or achieving smooth deceleration during hoist braking.

.jpg)

Core Roles in the PCS6000 System

Grid Synchronization and Power Converter: In wind power/energy storage scenarios, phase modules achieve precise synchronization between the generator and the grid (e.g., meeting IEC 61000-2-4 harmonic standards). Combined with a three-level topology, it optimizes grid-side current harmonics and supports bidirectional power flow in four quadrants.

Dynamic Response Regulator: Rapidly adjusts phase to maintain voltage stability during grid fluctuations or load abrupt changes. Examples include soft-start functionality and active damping control in wind power converters to reduce gearbox impact; in energy storage systems, phase control enables precise management of battery charging and discharging, improving energy utilization efficiency.

System Protection and Diagnostic Node: Integrates voltage spike suppression (in conjunction with VLU units), DC bus protection, and remote monitoring interfaces to ensure high reliability and low maintenance costs in renewable energy scenarios.

Grid Synchronization and Compatibility: As the core control unit of the three-level topology converter, it achieves precise synchronization between the generator/energy storage device and the grid (phase deviation ≤ 0.5°) through high-precision phase detection and dynamic adjustment, meeting grid-connected current harmonic standards (e.g., IEC 61000-2-4, THD ≤ 5%) and optimizing the power factor (≥ 0.95).

Bidirectional Energy Flow Management: Supports four-quadrant operation, enabling full-process control of generation-grid connection-energy storage-discharge in wind power/energy storage scenarios. Active damping control suppresses the impact of grid fluctuations on the system, ensuring the stability and reliability of new energy power generation.

High Voltage/Large Capacity Adaptation: In conjunction with grid-side filters and voltage limiting units (VLUs), it suppresses voltage spikes and harmonics, protects the DC bus and motor insulation, and is suitable for high-voltage scenarios above 3.3kV, covering a power range of 3-36MW, meeting the needs of large-scale wind farms and energy storage power stations.

The Core Logic of Cross-System Role Differences

Technical Path Differentiation: The ACS6000 focuses on the precision and dynamic response of industrial motor control, with its phase module achieving direct torque control through DTC technology. The PCS6000 emphasizes the efficiency and compatibility of new energy grid connection and energy conversion, with its phase module achieving low harmonic output and high power factor operation through three-level topology and optimized pulse vector control.

Protection Mechanism Emphasis: The ACS6000 emphasizes rapid fault location and modular maintenance in industrial scenarios; the PCS6000 needs to meet grid protection standards, integrating grid voltage/current monitoring and active damping functions to adapt to the intermittent load characteristics of new energy scenarios.

.jpg)

Commonality in Modular Design: Both adopt a modular design, supporting rapid replacement and remote monitoring. However, the ACS6000 prioritizes the flexibility of multi-motor coordination, while the PCS6000 emphasizes interface compatibility and protocol adaptation with the grid (such as PROFIBUS DP and Modbus).

Cross-System Common Technical Features

Modularity and Scalability: Utilizes standardized interfaces (such as Anybus communication modules) to support rapid integration into different systems. Modular design enables fault isolation and rapid replacement, improving system availability.

Algorithm and Hardware Collaboration: Based on real-time phase calculation using DSP/MCU and precise conduction control of power devices (IGCT/thyristors), it achieves millisecond-level phase regulation response, adapting to the differentiated needs of industrial drives and new energy scenarios.

Integrated Protection and Diagnosis: Integrates multi-level protection mechanisms (hardware overcurrent protection + software algorithm monitoring) and fault self-diagnosis functions. Collaboration with a host computer (such as an 800PEC controller) is achieved via RS485/CAN bus, supporting remote parameter adjustment and status monitoring.

Cross-System Differences and Collaboration Logic:

Technology Path Differentiation:

ACS6000 focuses on precise control in industrial drive scenarios (such as DTC technology), emphasizing torque/speed response on the motor side; PCS6000 focuses on grid compatibility in new energy scenarios (such as low harmonic design), emphasizing grid-side power quality and bidirectional flow capability.

Modular Design Advantages

The S-053M 3BHB012897R0003 module uses standardized interfaces (such as Anybus communication modules), allowing for rapid integration into different systems and adaptability to industrial drive or new energy scenarios through parameterized configuration. For example, it can be configured as a motor control mode in the ACS6000 and switched to grid synchronization mode in the PCS6000.

Common Reliability Design Features

Both systems employ a fuse-free design, arc protection, and a modular hot-swappable structure to ensure system availability in high-power scenarios. For example, within the 3-36MW power range, minute-level maintenance is achieved through rapid replacement of the phase module.

In summary, the S-053M 3BHB012897R0003 phase module plays a core role in the precise

control of industrial drives and the conversion of new energy power in the

ACS6000 and PCS6000 systems, respectively. Through phase regulation, power

adjustment, and protection diagnostics, it ensures efficient and stable system

operation, adapting to diverse application scenarios from metallurgical rolling

mills to wind power converters.

Related product recommendations:

3BHB009885R0013 S-093M

3BHB009885R0052 S-097H

3BHB009885R0063 S-093M

3BHB009885R0005 S-093H

3BHB009885R5311 S-093R

35SHY3545L0014 S-073N

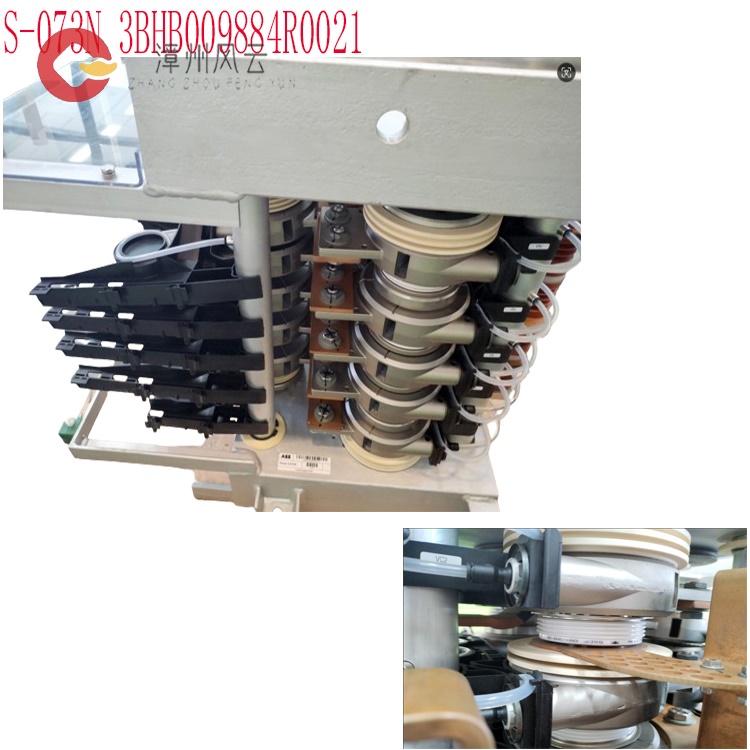

3BHB009884R0021 S-073N

3BHB009885R0052 S-097H

3BHB030478R0309 S-093H

3BHB012897R0003 S-053M

S-073N 3BHB009884R0021

3BHE041430R0001 ABB

3BHE041429R0001 ABB

3BHE041418R0001 ABB

3BHE041414R0001 ABB

3BHS393721 E01 ABB

3BHS600000 E40 ABB

3BHS606571 E49 ABB

3BHS537463 E72 ABB

3BHS600000 E87 ABB

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102