.jpg)

.jpg)

.jpg)

.jpg)

The modular design facilitates system expansion and upgrades. Users can select different module combinations to meet diverse control requirements. Multiple communication interfaces, such as Ethernet and serial ports, facilitate data exchange and integration with other devices or systems. Support for multiple programming languages and configuration tools, such as Control Builder M and ABB 800xA Configuration Studio, facilitates system programming and configuration. Equipped with a high-performance processor, it can rapidly process large amounts of control commands and data, ensuring real-time performance and stability. In scenarios such as production line control, robotics control, and material handling, this control unit enables precise control and collaborative operation of equipment, improving production efficiency and product quality.

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for photos to be taken at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your product. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

PFCA401SF 3BSE024387R4 Other Names:

PFCA401SF 3BSE024387R4 Excitation Unit PCL Controller

PFCA401SF 3BSE024387R4 Zone Controller Module

PFCA401SF 3BSE024387R4 Millmate 400 Controller Unit

PFCA401SF 3BSE024387R4 is an industrial control unit from ABB, part of its System 800xA or Advant Controller series. This control unit is typically used in process automation, power automation, or industrial manufacturing, performing core functions such as data acquisition, logic control, and signal processing. It is a key component of ABB's distributed control systems (DCS) or programmable logic controllers (PLCs).

Core Functions

High-Performance Processing: The PFCA401SF 3BSE024387R4 control unit is equipped with a high-performance processor capable of rapidly processing large amounts of control instructions and data, ensuring real-time and stable system operation.

Modular Design: The modular design facilitates system expansion and upgrades. Users can select different module combinations to meet diverse control requirements.

Comprehensive Interfaces: A variety of communication interfaces, such as Ethernet and serial ports, are provided to facilitate data exchange and integration with other devices or systems.

High Reliability: ABB control units are generally characterized by high reliability and stability, enabling long-term stable operation in harsh industrial environments, reducing failure rates and maintenance costs.

Easy Programming and Configuration: Supports multiple programming languages and configuration tools, such as Control Builder M and ABB 800xA Configuration Studio, facilitating user-friendly system programming and configuration.

Process Control: Executes logic such as PID regulation, sequential control, and interlock protection.

Data Acquisition: Connects analog (such as temperature and pressure) and digital (such as switch status) sensors to collect real-time field data.

Signal Processing: Supports signal input/output for current (4-20mA), voltage (0-10V), and digital pulse signals.

Communication Support: Integrated protocols such as Industrial Ethernet (e.g., Modbus TCP, OPC UA) and fieldbus (e.g., Profibus, DeviceNet) enable interconnection with host computers, HMIs, or other devices.

Redundancy: Supports dual-system hot standby to ensure high system availability.

Typical

Application Scenarios

Factory Automation: In scenarios such as production line control, robotics, and material handling, the PFCA401SF 3BSE024387R4 control unit enables precise control and coordinated operation of equipment, improving production efficiency and product quality.

Process Control: In process industries such as chemical, petroleum, and natural gas, this control unit can be used to monitor and control various parameters in the production process, ensuring stability and safety.

Energy Management: In energy sectors such as power and water, the PFCA401SF 3BSE024387R4 control unit can be used for intelligent energy scheduling and optimized management, reducing energy consumption and operating costs.

Power Industry: Power plant boiler control, steam turbine protection, and substation automation.

Petrochemical Industry: Reactor temperature control, pipeline pressure monitoring, and safety interlock systems.

Water Treatment: Pump station control, water quality analysis, and flow regulation.

Manufacturing Industry: Production line automation, robot collaborative control, and quality inspection.

Hardware

Structure

Modular Design: Hot-swappable for easy maintenance and expansion.

Interface Types:

Front-end Interface: Connects sensors and actuators (e.g., terminal blocks, M12 connectors).

Back-end Interface: Ethernet, serial port (RS232/RS485), or fiber optic communication.

Indicators: Status indicators for power, operation, and faults, enabling quick diagnosis.

Software Support

Programming Environment: Compatible with ABB Control Builder or Automation Builder software, supporting programming languages such as Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST).

Firmware Upgrade: Online updates via USB or network interface to fix bugs or add new features.

Diagnostic Tools: Built-in self-test functions generate fault logs and can be remotely monitored via the ABB System 800xA operator station.

Maintenance

and Troubleshooting

Regular Inspections: Clean interfaces, tighten terminals, and check indicator light status.

Common Faults:

No output: Check the power supply, fuses, and I/O module connections.

Communication interruption: Verify the IP address, subnet mask, and gateway configuration.

Abnormal data: Calibrate sensors or check the analog input range.

Spare Parts Management: It is recommended to stock frequently used modules (such as power supplies and CPUs) to minimize downtime.

Summary

The PFCA401SF 3BSE024387R4 is a core component in ABB's industrial control portfolio, widely used in the process automation industry for its high reliability, flexibility, and compatibility. When selecting a model, consider the specific application scenario and leverage ABB's software tools and global service network to achieve optimal control results.

All products on this website are special

editions, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are currently available for sale, so please contact customer service.

Related

product recommendations:

PFCL201C

10KN 3BSE027070R10

PFCL201CE

10KN 3BSX105983-100

PFCL201CE

50KN 3BSX802939-108

PFEA111-20

3BSE028140R0020

PFEA111-65

3BSE050090R65

PFEA112-20

3BSE030369R0020

PFEA112-20

3BSE050091R20

PFEA112-65

3BSE050091R65

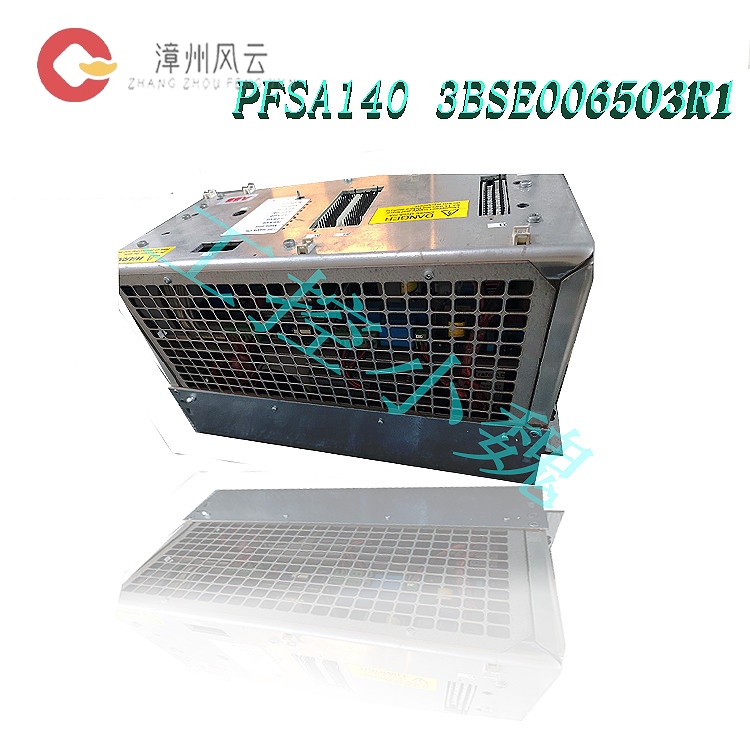

PFSA140RULLM1I

3BSE06503R1

PM150

3BSE003641R1

PM861K01

3BSE018105R1

PM866A

3BSE076359R1

PM891

3BSE053240R1

ABB

3BHE055094R0002

GBU72

3BHE055094R0002

ABB

3BHB030310R0001

ABB

3BHE031197R0001

ABB

3BHE055094R0002

GBU72

3BHE055094R0002 3BHB030310R0001

3BHE055094R0002

3BHE031197R0001

ABB

3BHB030310R0001

ABB

3BHE031197R0001

ABB

3BHE055094R0002

ABB

3BHB050206R0100

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102