.jpg)

.jpg)

.jpg)

.jpg)

Through the closed-loop feedback system (such as encoders and sensors), the driving force of the reel is adjusted in real time to ensure constant material tension and avoid breakage or relaxation. This is matched with the speed of the main production line, multi-axis coordinated motion control is achieved, the reel retraction and release position is accurately controlled, and automatic reel changing or positioning requirements are supported.

Many products are not yet on the shelves, please contact us for more products

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation

We have 76 shared warehouses around the world, so sometimes it may take several hours to accurately return to you, please understand. Of course, we will respond to your concerns as soon as possible.

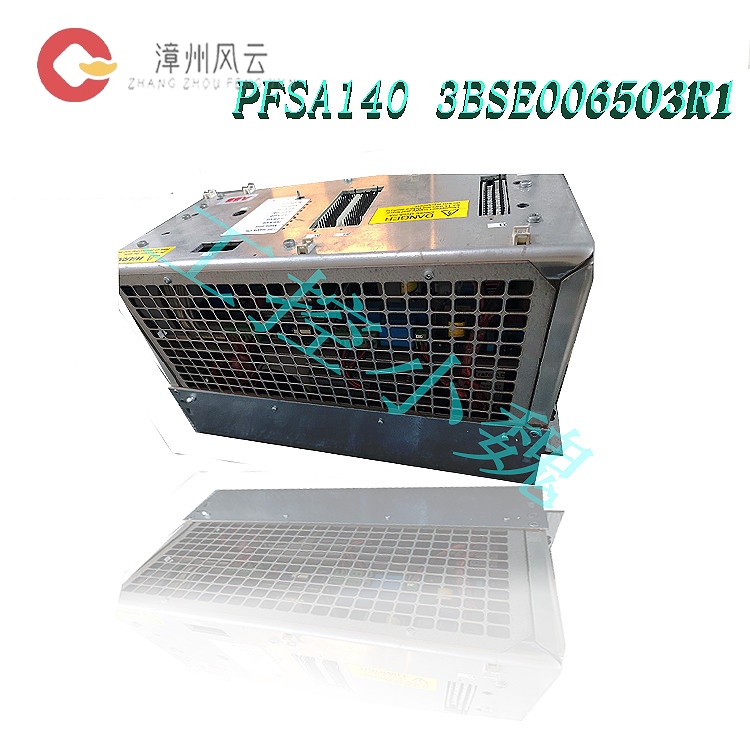

3BSE06503R1 Other names:

Tension controller unit 3BSE06503R1

3BSE06503R1 pressure controller

Tension sensor 3BSE06503R1

3BSE06503R1 is a reel supply controller produced by ABB, which is a key component in the field of industrial automation control. It is usually used in scenarios where the feed, tension or speed of reel materials (such as paper, film, metal strip, etc.) need to be accurately controlled, such as packaging machinery, printing equipment, textile machinery or metal processing production lines.

Core functions

Tension control: adjust the drive force of the reel in real time through a closed-loop feedback system (such as encoders and sensors) to ensure constant material tension and avoid breakage or relaxation.

Speed synchronization: match the speed of the main production line to achieve multi-axis collaborative motion control.

Position control: accurately control the reel retraction and release position to support automatic reel change or positioning requirements.

Fault diagnosis: integrated self-check function, which can monitor motor status, sensor signal abnormalities, and trigger alarms or shutdown protection.

Automatic deviation correction: detect material deviation through sensors, automatically adjust the reel position, and keep the material aligned.

Data monitoring and recording: real-time monitoring of operating parameters (such as tension, speed, temperature), support fault diagnosis and production data analysis.

Remote control and communication: support integration with host computers or PLCs through industrial networks (such as Modbus, Profibus) to achieve remote operation and centralized management.

Technical

features

Modular design: supports flexible configuration to adapt to different reel diameters, material widths and tension ranges.

High-precision control: ABB's advanced control algorithms (such as PID and fuzzy control) are used, with fast response speed and high stability.

Communication interface: Usually equipped with industrial bus interfaces such as Profibus, EtherCAT, Modbus, etc., which are easy to integrate with PLC, HMI or host computer systems.

Compatibility: It can be used with ABB's ACS880, ACS550 and other inverters or drives to form a complete drive solution.

Durability: Industrial-grade hardware design, adaptable to harsh environments (such as high temperature, dust, vibration), and the mean time between failures (MTBF) exceeds 50,000 hours.

Energy-saving optimization: Intelligently adjust motor power, reduce energy consumption, and meet green manufacturing standards.

Application

scenarios

Packaging industry: Control the conveying tension of packaging materials to ensure sealing or labeling accuracy.

Printing machinery: Maintain the smooth operation of paper during printing to prevent overprint deviation.

Textile machinery: Adjust the tension of yarn or fabric to improve product quality.

Metal processing: Control the winding and unwinding of materials such as steel strips and aluminum foil to avoid scratches or deformation.

New energy field: Ensure uniform material supply in the production of battery pole pieces and photovoltaic films.

Maintenance

and troubleshooting

Regular inspection: Clean the sensor, check whether the connecting cables are loose, and ensure that the vents are not blocked.

Parameter calibration: Regularly calibrate the tension sensor and encoder to avoid control deviation.

Common faults:

Tension fluctuation: Check the sensor signal or PID parameter setting.

Motor overload: Confirm whether the roll diameter calculation is correct or whether the mechanical part is stuck.

Communication interruption: Check the bus interface configuration or network connection stability.

Typical

case

After a packaging company adopted the 3BSE06503R1 controller, the film supply tension fluctuation dropped from ±5% to ±0.5%, the product defective rate decreased by 40%, and the annual material cost saved was about 200,000 yuan. At the same time, through the remote monitoring function, the maintenance personnel response time was shortened by 60%, and the comprehensive utilization rate of equipment was increased by 25%.

Summary

The 3BSE06503R1 reel feed controller is a core component in ABB's industrial automation solutions. With its high precision, reliability and flexibility, it is widely used in multiple industries. By optimizing the material supply process, it helps companies reduce costs and increase efficiency, and enhance market competitiveness.

All products on this website are special

products, and the market price has been fluctuating.

The specific quotation is subject to customer service, because the product is a new product and the price is not real.

Please confirm the model and product, price and other detailed information with customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Related

product recommendations:

3BSE003641R1

PM150

3BSE018105R1

PM861K01

3BSE053240R1

PM891

ABB

3BHE010360R0001

ABB

3BHE015881R0001

ABB

3BHB050206R0100

ABB

3BHE055094R0002

GBU72

3BHE055094R0002

ABB

3BHB030310R0001

ABB

3BHE031197R0001

ABB

3BHE055094R0002

GBU72

3BHE055094R0002 3BHB030310R0001

3BHE055094R0002

3BHE031197R0001

ABB

3BHB030310R0001

ABB

3BHE031197R0001

ABB

3BHE055094R0002

ABB

3BHB050206R0100

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102