.jpg)

.jpg)

.jpg)

.jpg)

The redundant design supports N+1 parallel connection. A single module failure does not affect system operation. It supports communication protocols such as CAN, RS485, and Modbus. It can be connected to the SCADA system for remote monitoring. It provides an LED display or LCD interface to display operating parameters and fault information in real time. It uses high-temperature resistant and electromagnetic interference-resistant capacitors and semiconductor devices, and the MTBF (mean time between failures) exceeds 50,000 hours.

Many products are not yet on the shelves. Please contact us for more products.

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation.

We have 76 shared warehouses around the world, so sometimes it may take several hours to accurately return to you, please understand. Of course, we will respond to your concerns as soon as possible.

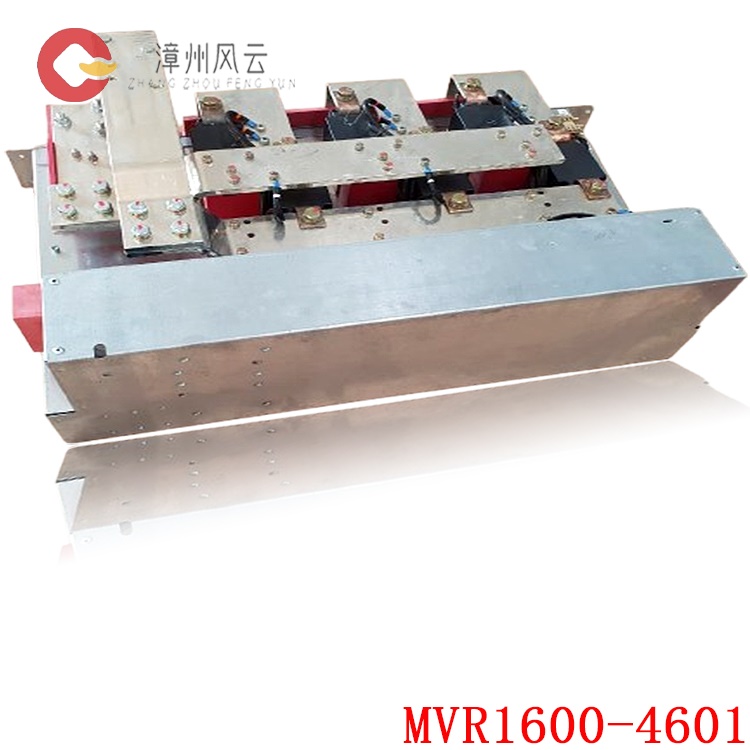

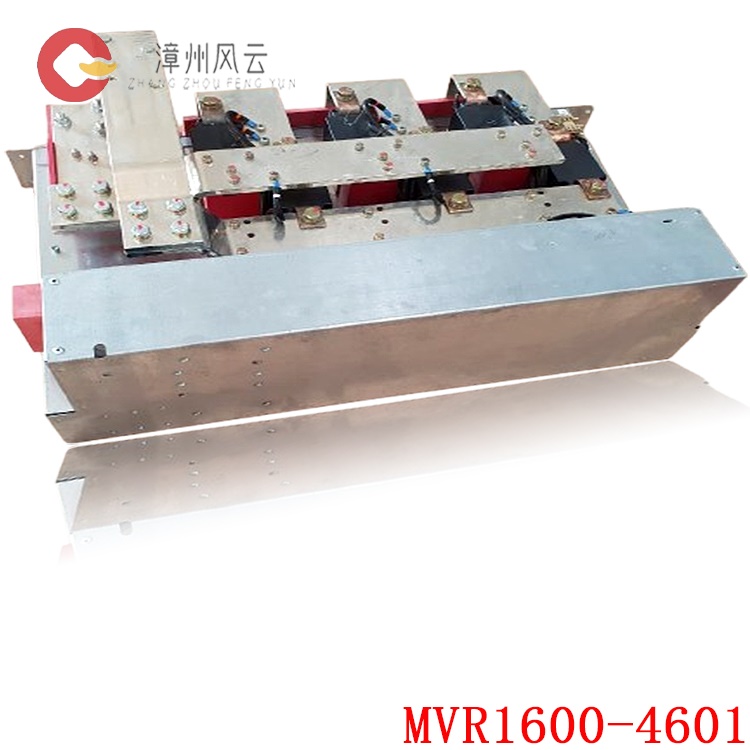

Other names of MVR1600-4601-A:

Excitation unit MVR1600-4601-A

MVR1600-4601-A air-cooled rectifier module

Input and output unit MVR1600-4601-A

MVR1600-4601-A rectifier module is a high-reliability power electronic device designed by GE for medium and high-power DC power supply needs. It adopts advanced rectification technology and modular design, and has the characteristics of high efficiency, stability, and easy maintenance. This module is usually used as the core component of the DC power supply system to provide stable DC power to the load, while supporting parallel expansion to meet higher power requirements.

Features

High reliability design

IGBT or SCR is used as the core rectifier element, with fast protection and self-recovery capabilities;

Redundant design supports N+1 parallel connection, and single module failure does not affect system operation;

Overvoltage, overcurrent, overheating, short circuit and other protection functions are complete to ensure the safety of equipment and load.

Intelligent control

Integrated microprocessor (MCU) or digital signal processor (DSP) to achieve precise voltage/current control;

Support CAN, RS485, Modbus and other communication protocols, can be connected to SCADA system for remote monitoring;

Provide LED display or LCD interface to display operating parameters and fault information in real time.

Modularity and scalability

Standard 19-inch rack design, compatible with a variety of cabinet structures;

Support parallel expansion, up to 8 modules can be connected in parallel to meet 12.8kA current demand;

High precision of current sharing control between modules (≤±5%) to ensure system stability.

Input: three-phase AC, may support 380V/400V/460V, etc., frequency 50/60Hz.

Output: DC voltage or customized according to needs, power 1600W.

Efficiency: high-efficiency design, reducing energy consumption and heat generation.

Protection function:

Overvoltage/undervoltage protection

Overcurrent/short circuit protection

Overtemperature protection

Input surge suppression

Environmental adaptability:

Operating temperature range: -40℃ to +70℃ (industrial grade)

Protection level: IP20/IP30 (dustproof and anti-electric shock)

Anti-seismic design: adapt to transportation and vibration environment.

High-efficiency design

Conversion efficiency: typical efficiency ≥95%, some models can reach 98%, significantly reducing energy consumption and heat dissipation costs.

Power Factor Correction (PFC): Built-in active PFC circuit, power factor ≥ 0.99, reducing reactive power loss, in line with IEC 61000-3-2 standard.

Wide input range: Supports three-phase 380V AC (±20%) or single-phase 220V AC input to adapt to grid fluctuations.

High reliability guarantee

Industrial-grade components: Adopt high-temperature resistant and electromagnetic interference-resistant capacitors and semiconductor devices, with MTBF (mean time between failures) exceeding 50,000 hours.

Redundant design: Supports N+1 or N+X redundant configuration, and single module failure does not affect system operation.

Hot-swap function: Modular design, supports online replacement, and maintenance does not require downtime.

Intelligent management

Digital monitoring: Real-time transmission of voltage, current, temperature and other parameters through RS485/CAN/Ethernet interface.

Remote control: Supports SNMP, Modbus and other protocols, integrated into the power environment monitoring system (DCIM).

Predictive maintenance: built-in sensors monitor the life of key components (such as capacitors and fans) and warn of failures in advance.

Environmental protection and safety

Low harmonic pollution: total harmonic distortion (THD) ≤5%, in line with IEEE 519 standards.

Safety certification: UL, CE, CCC and other certifications, with multiple protections such as overvoltage/undervoltage, overcurrent, short circuit, overtemperature, etc.

Environmental adaptability

Operating temperature range: -10℃ to +50℃ (need to be derated for use beyond the range);

Strong anti-electromagnetic interference (EMI) capability, in line with IEC 61000 standards;

Anti-seismic design, adaptable to industrial site vibration environment.

Typical application scenarios

Power industry

Substation DC power supply system, providing reliable power supply for circuit breaker operating mechanism and protection device;

Power plant excitation system, controlling the output voltage stability of the generator.

Industrial Automation

DC power supply for electrolysis, electroplating, welding and other processes;

DC motor drive systems, such as transmission control in metallurgy, mining, papermaking and other industries.

New Energy Field

Photovoltaic inverter test platform, simulating DC bus voltage;

DC charging/discharging control of energy storage system (BESS).

Rail Transportation

The traction power supply system of subways and high-speed railways provides DC traction for trains;

DC power supply for signal systems to ensure driving safety.

Maintenance and Troubleshooting

Daily Maintenance

Cleaning: Regularly clean the dust on the surface of the module to prevent poor heat dissipation;

Inspection: Observe the running status of the fan to ensure no abnormal sound or jamming;

Testing: Use a multimeter to measure input/output voltage and current to verify parameter stability.

Spare Parts Management

Reserve commonly used wearing parts (such as fans, fuses, IGBT modules);

Regularly replace electrolytic capacitors (lifespan is about 5-8 years) to prevent capacity attenuation from causing unstable output.

All products on this website are special products, and the market

price has been fluctuating.

The specific quotation is subject to the customer service. Because the product is a new product, the price is not real.

Please confirm the model and product, price and other detailed information with the customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Related product recommendations:

VMIVME-2128

151X1235DB15NP03

151X1235DB10SA01

151X1235DB15SA03

151X1207DC13SA21

151X1235DB15SA01

151X1235BC01SA01

151X1233DB01SA01R3

151X1233DB01SA01R4

151X1233DB01SA01R

151X1235DB15SA02

IC660BA104

VME-7807RC-424001

VMIVME-7807RC

VMIVME-017807-414001

VMIVME-7807

VMIVME-7750-834

VMIVME-7740-850

VMIVME-7698

VMIVME-2170A

VMIVME-2540

VMIVME-7750-744001

VMIVME-7700

VMIVME-7658-330

VMIVME-7486

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102