.jpg)

.jpg)

.jpg)

.jpg)

Based on DTC technology, it achieves precise control of motor torque and speed with fast response speed, which is suitable for dynamic process requirements (such as steel blast furnace blowers and NASA wind tunnel projects). It adopts high-speed ADC sampling (frequency ≥ 10kHz) and dynamic compensation algorithm to quickly adjust the trigger angle when the load suddenly changes (such as fan startup), reduce current impact (such as rolling mill startup current is reduced by 40%), and stabilize the power grid fluctuation to within ±5%.

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for photos to be taken at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return your order. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

3BHB009885R0002 Other Names:

High-Voltage Inverter 3BHB009885R0002

3BHB009885R0002 Direct Torque Controller (DTC)

Modular AC Drive 3BHB009885R0002

3BHB009885R0002 High-Pulse Phase Module

As a core component of the ACS6000 system, the 3BHB009885R0002 phase control module monitors and precisely adjusts the three-phase voltage and current phases in real time, ensuring a phase synchronization error of less than 0.1° during coordinated operation of multiple motors, thus preventing harmonic surges, motor overheating, or shutdown risks.

Using high-speed ADC sampling (frequency ≥10kHz) and a dynamic compensation algorithm, it rapidly adjusts the trigger angle during sudden load changes (such as fan startup), reducing current surges (e.g., a 40% reduction in rolling mill startup current), and stabilizing grid fluctuations to within ±5%.

Key Technical Parameters

Input Configuration: Supports 6-, 12-, and 24-pulse diode rectification or 18-pulse active rectification. Input voltage range: 3300V (6-pulse) to 3160V (active rectification), frequency: 50/60Hz, power factor >0.95 (diode rectification) or adjustable to 1.0 (active rectification).

.jpg)

Output Characteristics: Output voltage: 2.3/3.3kV, frequency: 0-75Hz, efficiency >98%, supports induction motors, synchronous motors, and permanent magnet synchronous motors.

Environmental Adaptability: Operating temperature: -25°C to +70°C, IP20 protection level (optional IP42/IP54), altitude: 0-2000m (higher altitude with derating).

Core

Functions and Technical Features

Direct Torque Control (DTC): Based on DTC technology, this achieves precise control of motor torque and speed, with fast response, suitable for dynamic process requirements (such as steel blast furnace blowers and NASA wind tunnel projects). Modular Design: Supports single or multiple motor drives, adapting to different power levels and voltage requirements (input voltage 3300V/1725V, output 2.3-3.3kV) through flexible combinations of power modules (e.g., 3-36MW) and rectifier units (6/12/24-pulse). IGCT power devices reduce component count by 30%, improving reliability and adapting to harsh environments such as metallurgy, mining, and chemical industries.

The modules are hot-swappable, reducing replacement time to 20 minutes. Built-in pre-diagnostic features (temperature and voltage monitoring) provide 72-hour advance warning of faults, such as phase drift caused by capacitor aging.

High-Reliability Components: Utilizing IGCTs (Integrated Gate Commutated Thyristors) and diodes, combined with a fuseless design, reduces failure points and improves system stability.

High efficiency and energy saving: System efficiency >98%, power factor >0.95 (diode rectifier) or adjustable to 1.0 (active rectifier), achieving annual energy savings of up to 16 GWh (as in the SSAB Oxelösund case).

Installation

and Commissioning Key Points

Safety Regulations:

Before commissioning, disconnect the power supply and connect to ground. Use a multimeter to test the IGCT gate-cathode voltage (-20 VDC/+0.7 VDC) to avoid short-circuit risks.

Wear protective equipment when operating the DC link to prevent arcing hazards.

Configuration Process:

Cold commissioning: Check the main circuit breaker, transformer, motor wiring, and cooling system to ensure there are no ground faults.

Hot commissioning: Verify control logic, protection functions (e.g., overload and short-circuit protection), and communication protocol (Profibus/Modbus) compatibility.

Maintenance Guidelines:

Regularly check the IGCT and diode status. Use a fiber optic cable to connect the gate unit for optical testing.

Troubleshooting: Use LED indicators, DriveWindow software, or control panel error codes to locate the problem. For example, if the main circuit breaker fails to close, check the charging logic and timeout settings.

Common Faults: ARU OverCurrent and Di/Dt faults are often caused by aging clamping diodes, degraded IGCT performance, or insulation failures. For example, a coal mine hoist tripped due to unstable performance of the A-phase clamping diode VC1. Replacement restored normal operation.

Diagnostic Steps:

Use a datalogger to monitor current/voltage waveforms to identify "false current" or true overcurrent.

Check the phase module IGCT on/off characteristics, clamping diodes, and copper busbar insulation (e.g., carbonization or discharge marks).

Verify the performance of the deionization tank (replace every two years) to ensure the efficiency of the water cooling system.

Maintenance Recommendations: Regularly test module performance. Spare phase modules can reduce downtime. Tightening and insulation testing of high-voltage switchgear/transformer terminals are essential.

Application

Scenarios and Advantages

Industrial Applications: Widely used in steel, mining, ship propulsion, power generation, and aerospace (such as NASA's 101MW wind tunnel project), meeting high-power, high-precision control requirements.

Multi-Motor Synergy: For example, in steel mill clusters and paper machine rewinders, eight motors are synchronized via a common DC bus, reducing paper tension fluctuations from ±3% to ±1% and achieving 92% brake energy recovery efficiency.

Energy Saving and Efficiency Optimization: In chemical pump and compressor applications, phase control reduces harmonics (THD <3%), complying with IEEE 519 standards, saving approximately 1.2 million kWh of electricity annually and reducing carbon emissions by 800 tons.

.jpg)

Heavy-Duty Industrial Applications: When loads suddenly change in mine hoists and crushers, the phase module maintains stable motor torque to prevent overload damage. Wind turbine pitch control systems improve power generation efficiency through precise phase control.

Special Features:

Soft start function extends motor life and reduces mechanical stress.

Power Failure Ride-Through function maintains operation during voltage fluctuations, avoiding downtime.

Multi-motor synchronous control achieves load balancing and optimizes energy efficiency.

Environmental adaptability: Protection rating IP32-IP54, operating temperature 0-40°C (derating and expandable), altitude 0-2000 meters.

Summary

The 3BHB009885R0002 phase control module is the core of the ACS6000 system, enabling high-precision phase control, multi-motor coordination, and energy-saving operation. Its high reliability, dynamic response, and modular design make it an excellent choice for heavy-duty industrial applications such as metallurgy, mining, and chemical processing. However, regular maintenance and fault prediction are essential to ensure continuous and efficient system operation.

All products on this website are special

products, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices may not be accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are for sale. Please contact customer service for inquiries.

Related

product recommendations:

3BHB009885R0013

S-093M

3BHB009885R0052

S-097H

3BHB009885R0063

S-093M

3BHB009885R0005

S-093H

3BHB009885R5311

S-093R

35SHY3545L0014

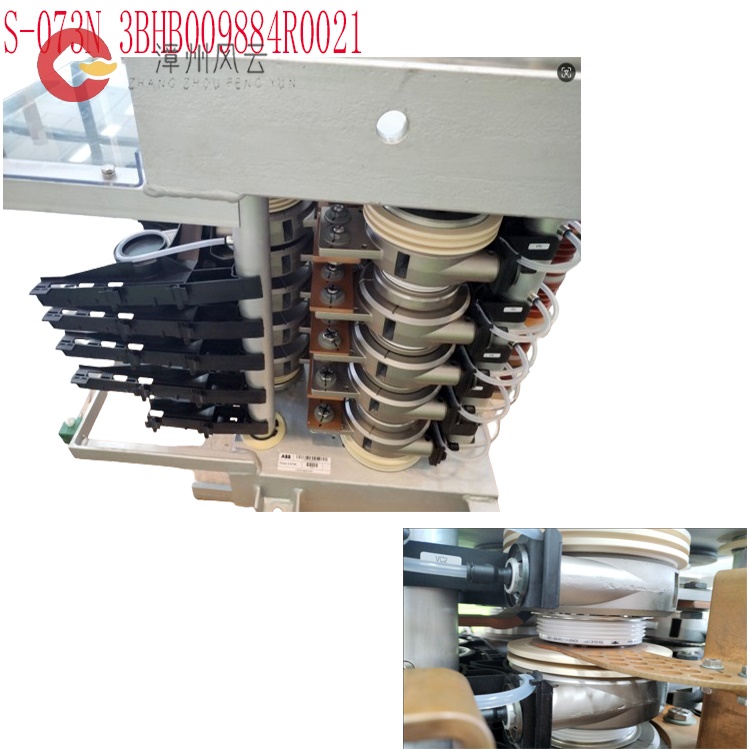

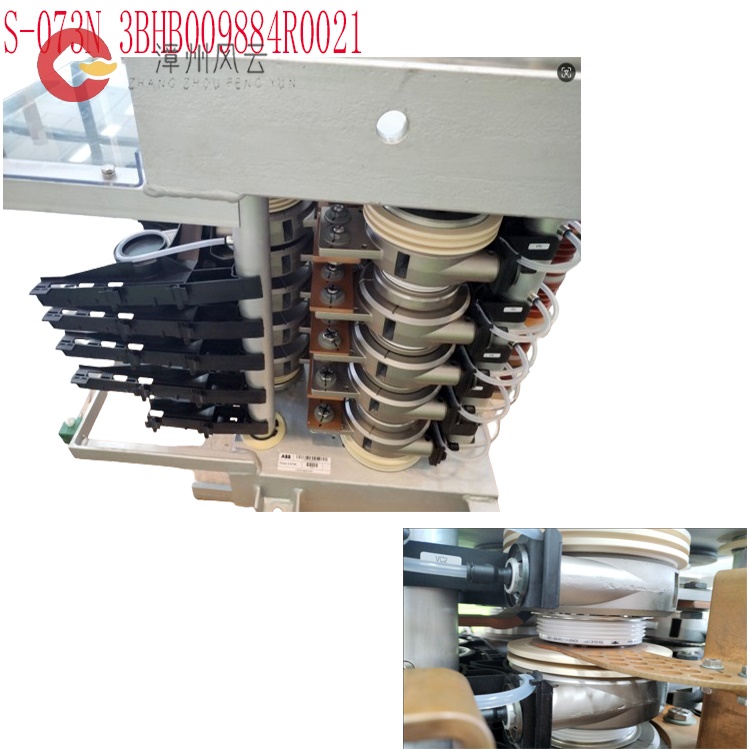

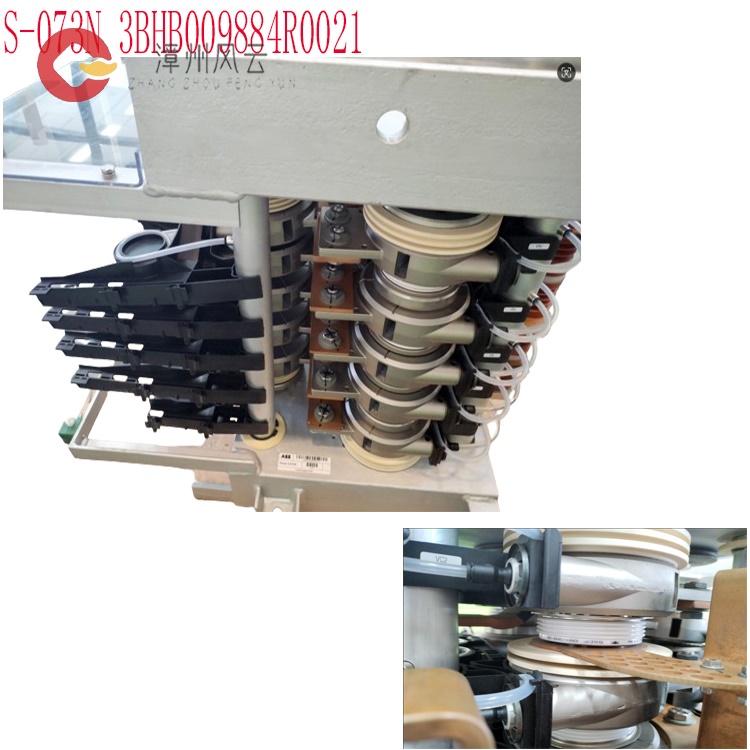

S-073N

3BHB009884R0021

S-073N

3BHB009885R0052

S-097H

3BHB030478R0309

S-093H

3BHB012897R0003

S-053M

S-073N

3BHB009884R0021

3BHE041430R0001 ABB

3BHE041429R0001 ABB

3BHE041418R0001 ABB

3BHE041414R0001 ABB

3BHS393721 E01 ABB

3BHS600000 E40 ABB

3BHS606571

E49 ABB

3BHS537463

E72 ABB

3BHS600000

E87 ABB

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102