.jpg)

.jpg)

.jpg)

.jpg)

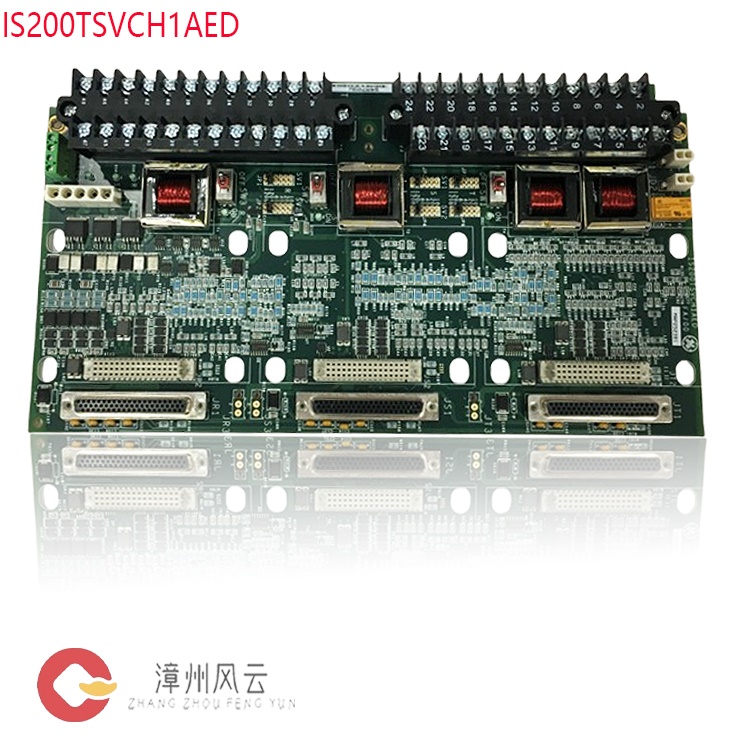

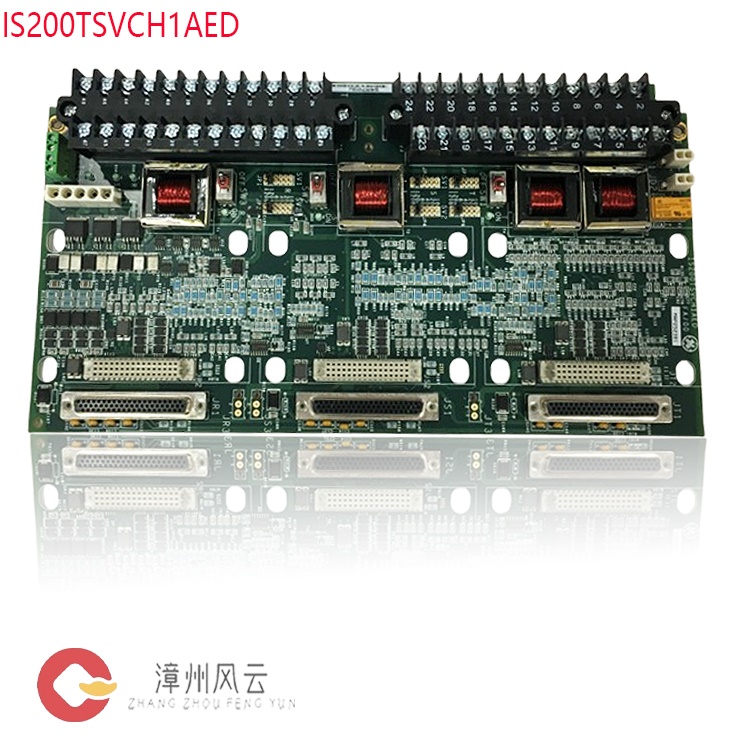

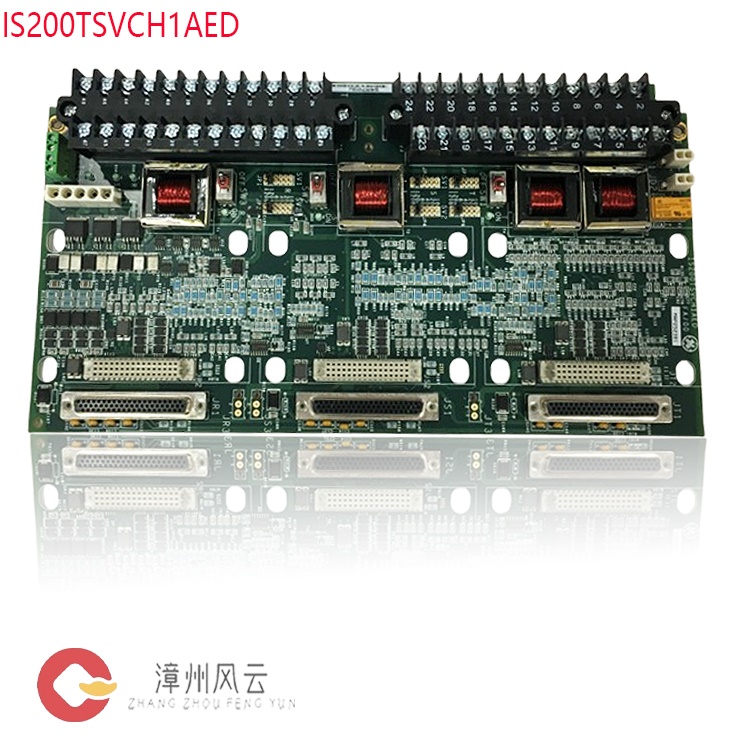

This GE interface board uses high-temperature resistant, moisture-proof, and vibration-resistant materials to adapt to harsh industrial environments; it supports hot-swapping and self-diagnostic functions for easy maintenance and rapid fault location; high-precision signal conversion and real-time data processing ensure data accuracy; it supports standard communication protocols (such as Modbus and Profinet) for easy integration with other devices or systems; it supports flexible expansion to adapt to different project needs; and it is compatible with GE's redundant control system to improve system reliability.

Many products are not yet listed. Please contact us for more product information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to return an accurate result. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

Other names for IS200UCVIH1AEC:

Input/Output Module IS200UCVIH1AEC

IS200UCVIH1AEC Communication Module

Analog Module IS200UCVIH1AEC

Core Features

Functional Positioning: As a signal transmission and processing hub, it supports the conversion and integration of various input/output signals (such as digital and analog signals), is compatible with distributed control systems (DCS) such as GE Mark VI/VIe, and achieves precise interaction between physical and digital signals.

Industrial-Grade Design: Utilizes high-temperature resistant, moisture-proof, and vibration-resistant materials, adapting to harsh industrial environments; supports hot-swapping and self-diagnostic functions for easy maintenance and rapid fault location.

Signal Processing Capabilities: High-precision signal conversion and

real-time data processing ensure data accuracy; supports standard communication

protocols (such as Modbus and Profinet) for easy integration with other devices

or systems.

Expandability: Modular design supports flexible expansion to adapt to different project needs; compatible with GE's redundant control systems, improving system reliability.

Other Typical Models:

IS200 Series: Such as IS200BICIH1AEC (encoder input/main board), IS200WETAH1AEC (turbine controller), IS200HSLAH2ADE (turbine protection and monitoring), supporting high-precision signal acquisition and real-time transmission.

DS200 Series: Such as DS200ADGIH1AAA (auxiliary interface board), DS200DMCAG1AGB (rectangular interface board), used for drive unit cabinets or power management.

IC660 Series: Such as IC660ELB912 (µGENI network interface board), supporting industrial network communication.

Mark Series: Examples include the DS200ADGIH1AAA (Mark V auxiliary interface board, including 40-pin/6-pin connectors, supporting 60 jumpers, for gas/steam turbine control) and the IS200BICIH1AEC (encoder input/main board, compatible with Mark VI/VIe systems).

.jpg)

Bus Interface Modules: Examples include the 8515-BI-PN (dual 10/100Mbps RJ45 interfaces, supporting the entire PAC8000 series of IO modules, G3 corrosion certified, suitable for environments from -40 to 70℃).

Excitation Control Boards: Examples include the IC752SPL013 (for power plant excitation systems, supporting Ethernet/Profinet IO communication for stable voltage/frequency control).

High-Speed Communication Boards: Examples include the GEC single board (1GE Combo interface, supporting automatic switching between optical and electrical ports, compatible with IPv4/IPv6/MPLS protocols).

Technical Features:

High-Speed Transmission: Gigabit Ethernet (GE interface) supports 1Gbps speeds, compatible with fiber optic/copper cables, and supports full-duplex communication.

Industrial-Grade Reliability: High temperature resistant, moisture-proof, and vibration-resistant; CE and UL certified; suitable for harsh environments such as gas turbines, oil and gas processing, and smart grids.

Compatibility and Scalability: Supports standard protocols (such as Ethernet and Profinet); modular design facilitates system expansion and hot-swappable maintenance.

Application Scenarios:

Energy Sector: Widely used for signal monitoring and data processing in power generation equipment such as gas turbines and steam turbines; used for real-time monitoring of parameters such as pressure, flow rate, and temperature in oil and gas processing facilities.

Manufacturing: Used for process control and equipment status monitoring in production lines to optimize production efficiency; supports signal integration of automated equipment (such as PLCs and servo motors) in manufacturing.

Infrastructure: Enables energy management and equipment control in smart grids; applied to remote monitoring and data acquisition of water treatment and environmental protection equipment.

Technical Details

Interface Configuration: Includes digital input/output ports (e.g., DI5 emergency stop function, DI7 start/stop control), analog signal interfaces, and communication ports, supporting the connection of various types of sensors and actuators.

Safety Features: Built-in grounding protection and shielded grounding design, complying with industrial safety standards (e.g., grounding resistance ≤100Ω); supports alarm functions and fault self-diagnosis to ensure system safety.

Compatibility: Seamlessly integrates with GE's DCS systems, robot control systems (e.g., ABB, KUKA), and third-party industrial control equipment; supports modular expansion and system upgrades.

Troubleshooting and Maintenance:

Common Issues:

Physical Connection Faults: Incompatible optical module types, abnormal fiber optic/copper cable connections, interface contamination.

Configuration Issues: Inconsistent duplex mode/rate settings, protocol compatibility errors.

.jpg)

Troubleshooting Steps:

Check Hardware Connections: Confirm that the optical module and fiber optic/copper cable are securely inserted and of the correct type.

Verify Configuration Consistency: Use the `display interface` command to check the interface status and configuration.

Test Loopback Functionality: Troubleshoot board failures through local loopback testing.

Contact Technical Support: If the problem persists, collect logs and configuration files and contact GE engineers.

Latest Developments and Trends

Technological Evolution: GE interface boards are evolving towards higher bandwidth (e.g., 10G/40G), lower latency, and greater intelligence (integrated AI diagnostics).

Expanding Industry Applications: Applications continue to deepen in fields such as new energy, intelligent manufacturing, and smart cities.

All products on this website are special products, and market prices

are constantly fluctuating.

Please refer to customer service for a quote, as the price is not accurate for new products.

Please confirm the model, product, price, and other detailed information with customer service before placing an order. This website is currently in use.

New products are available for sale; please contact customer service for further information.

Recommended related products:

GE IS200DSFCG1ADB

GE IS200TRLYH1FAA

GE IS200VPWRH1AJD

GE IS200VGENH1BCB

GE IS200ADIIH1AAA

GE IS200TRPGH1B

GE IS200AEBMG1AFB

GE IS200DAMAG1ACA

GE IS200DAMAG1A

GE IS200TREGH1BDB

GE IS200VSVOH1BDB

GE IS200VSVOH1BED

GE IS200BPIAG1AEB

GE IS200EDCFG1AED

GE IS200AEBMG1AEB

GE IS200VTCCH1C

GE IS200ECTBG1ACB

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102