.jpg)

.jpg)

.jpg)

.jpg)

Based on IGCT (Integrated Gate Commutated Thyristor) technology, it achieves ultra-high precision phase angle adjustment of ±0.1°, supports adjustable switching frequency of 2-5kHz, ensures synchronization of multi-phase power output, and reduces harmonic distortion. Typical efficiency ≥98%, conduction loss ≤2.0V, suitable for 6.0-6.9kV medium and high voltage systems, current range 300-1200A, expandable to 3-27MW power levels, supports dynamic voltage phase adjustment, and, in conjunction with DTC direct torque control algorithm, achieves precise matching of motor speed and torque, meeting the requirements of megawatt-level industrial drives (3-27 MW power range).

Many products are not yet listed. Please contact us for more product information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images, and we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

3BHB030478R0009 Other Names:

High Voltage Variable Frequency Module Frame Phase Module 3BHB030478R0009

3BHB030478R0009 High Tower Variable Frequency Module

Power Module 3BHB030478R0009

Core Functions and Technical Specifications

Precise Phase Control: Based on IGCT (Integrated Gate Commutating Thyristor) technology, it achieves ultra-high precision adjustment of the phase angle ±0.1°, supports adjustable switching frequencies of 2-5kHz, ensures the synchronization of multi-phase power output, and reduces harmonic distortion. Typical efficiency ≥98%, conduction loss ≤2.0V, suitable for 6.0-6.9kV medium and high voltage systems, current range 300-1200A, expandable to 3-27MW power levels, supports dynamic voltage phase adjustment, and with DTC direct torque control algorithm, achieves precise matching of motor speed and torque, meeting megawatt-level industrial drive requirements (3-27 MW power range).

Multi-phase power balancing: Built-in phase-locked loop (PLL) and high-speed ADC (1MHz sampling rate) monitor the phase difference of current/voltage in each phase in real time, and automatically allocate power ratio through algorithm to avoid single-phase overload, ensuring the stability of three-phase or multi-phase systems. It has ESD protection (±8 kV contact discharge/±15 kV air discharge) and is suitable for industrial environments with strong electromagnetic interference.

.jpg)

Fault Protection Mechanism: Integrated overvoltage (OVP, triggered at 110% rated voltage), overcurrent (OCP, triggered at 150% rated current), and overheat (OTP, activated at +90℃) three-level protection, with a response time of <1ms. Supports ESD protection (±8kV contact/±15kV air discharge), meeting IP20 protection standards (up to IP54 with appropriate cabinet mounting).

Communication and Interface: Supports Modbus RTU/TCP, Profinet RT, Ethernet/IP, and other protocols. Equipped with 2 channels of 4-20mA analog input, 8 channels of digital I/O, and ST-type fiber optic interface (electromagnetic interference resistant). Phase data update rate is 10ms, allowing seamless integration into DCS/SCADA systems.

High-Efficiency Power Conversion and Energy Saving:

Based on IGCT (Integrated Gate Commutated Thyristor) technology, with a switching frequency of 2-5 kHz, conversion efficiency ≥98%, and conduction loss ≤2.0 V, reducing power loss.

Supports both liquid cooling and air cooling modes, improving heat dissipation efficiency by 40% and adapting to a wide temperature range of -40℃ to +85℃.

Core Functions and Application Scenarios

Industrial Drives: In high-power applications such as metallurgy (rolling mills, continuous casting machines), mining (hoists, belt conveyors), and cement, precise phase control enables dynamic matching of motor speed and torque, achieving energy savings of 15-30%. For example, it optimizes roll synchronization accuracy in conjunction with the DTC direct torque control algorithm.

Technical Parameters

Electrical Specifications: Compatible with 6.0-6.9 kV AC system voltage, rated current 300-1200 A, compatible with ±10% grid fluctuations.

Communication Interfaces: Supports Modbus RTU/TCP, Profinet RT, Ethernet/IP protocols, and integrates 2 channels of 4-20 mA analog input, 8 channels of digital I/O, and an ST-type fiber optic interface (anti-electromagnetic interference).

.jpg)

Physical Characteristics: Module dimensions 220×180×45 mm, weight approximately 3.2 kg, aluminum casing, IP20 protection (IP54 with cabinet), supports modular installation and online hot-swapping.

Power System Auxiliaries:

Reactive Power Compensation: Adjusts phase in STATCOM (Static Synchronous Compensator) to improve power factor (to above 0.98), reducing grid harmonic pollution.

HVDC Transmission: Assists in phase synchronization during AC/DC conversion, ensuring stable operation of converter stations.

Grid Fault Ride-Through: Supports low-voltage/high-voltage ride-through (LVRT/HVRT), ensuring compliance with international standards such as GL-IV-2:2012 and CGC-R46022:2011 when wind/solar power is connected to the grid.

Renewable Energy Grid Connection: In wind power (especially offshore wind turbines) and solar power plants, phase synchronization ensures smooth grid connection of power, reducing curtailment rates. For example, the PCS6000 converter has proven its high reliability in 1,000 MW-class offshore wind power projects worldwide.

**Safety-Critical Scenarios:** Certified by SIL3 (IEC 61508) and PLe (ISO 13849), suitable for process control requiring high safety integrity, such as emergency shutdown systems and dynamic voltage restoration.

**Design Advantages and Reliability:**

**Modular Architecture:** Features a compact design (220mm × 180mm × 45mm), with an aluminum casing that balances heat dissipation and mechanical strength. Supports both air-cooled and liquid-cooled modes, with liquid cooling improving heat dissipation efficiency by 40%. Operating temperature range: -40°C to +85°C, suitable for harsh environments such as high altitudes and high temperatures.

**Redundancy and Diagnostics:** Built-in redundant DC UPS backup system ensures continuous control signals during power outages; high diagnostic coverage (99%) supports remote monitoring and preventative maintenance, reducing operating costs.

**Redundancy and Diagnostics:** Includes a built-in redundant DC UPS backup system to ensure continuous control signals during power outages; high diagnostic coverage (99%) supports remote monitoring and preventative maintenance, reducing operating costs. Compatibility and Expandability: Works seamlessly with ABB AC 800M series controllers (such as PM851 and PM861), supports IGCT module expansion to meet different power level requirements.

Application Scenarios

Industrial Drives: Metallurgical rolling mills, continuous casting machines, large fans/pumps/compressors, mine hoists, etc., achieving dynamic load-phase-torque matching with energy savings of 15-30%.

Power Systems: STATCOM reactive power compensation (power factor improved to above 0.98), HVDC converter station phase synchronization, grid harmonic mitigation.

New Energy: Wind power/photovoltaic power station converter phase synchronization to ensure stable grid connection; dynamic voltage repair and grid fault ride-through (such as low-voltage ride-through).

Special Scenarios: Railway grid connection, ship shore power systems, dynamic reactive power compensation, etc.

Design Advantages

Modular Architecture: Adapts to ACS6000 standard cabinets, supports multi-module parallel expansion (maximum 120 MVA), reducing footprint and maintenance costs.

Intelligent Diagnostics: Features a built-in NTC temperature sensor and status monitoring, providing real-time feedback on operating status via LED indicators/communication interface. Supports remote monitoring and fault code upload (e.g., "E01 Overvoltage").

Compatibility: Seamlessly integrates with the ACS6000 main controller (e.g., AC 800PEC), supporting customized control algorithms.

Summary

The 3BHB030478R0009 phase module is a core component of the ABB PCS6000 system. Through high-precision phase control, multi-phase power balancing, and fault protection mechanisms, it ensures stable operation of industrial drives and power systems. Widely used in metallurgy, wind power, and HVDC, it has become a key solution for high-reliability, high-efficiency medium-voltage power conversion thanks to its IGCT technology, modular design, and stringent safety certifications.

Please note that all products on this website are specialty items, and

market prices are constantly fluctuating.

Please refer to customer service for a specific quote, as the price may not be accurate for new products.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Related product recommendations:

3BHB009885R0013 S-093M

3BHB009885R0052 S-097H

3BHB009885R0063 S-093M

3BHB009885R0005 S-093H

3BHB009885R5311 S-093R

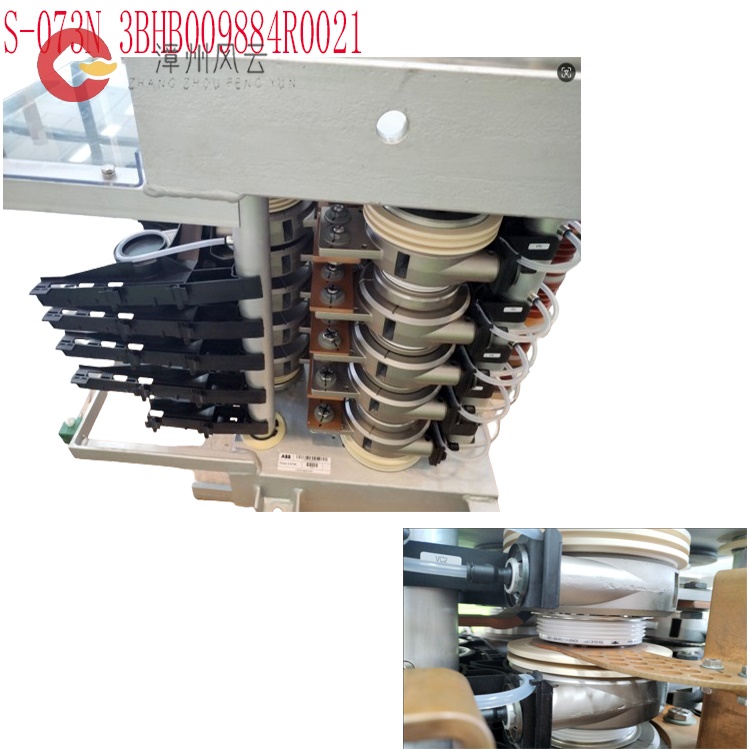

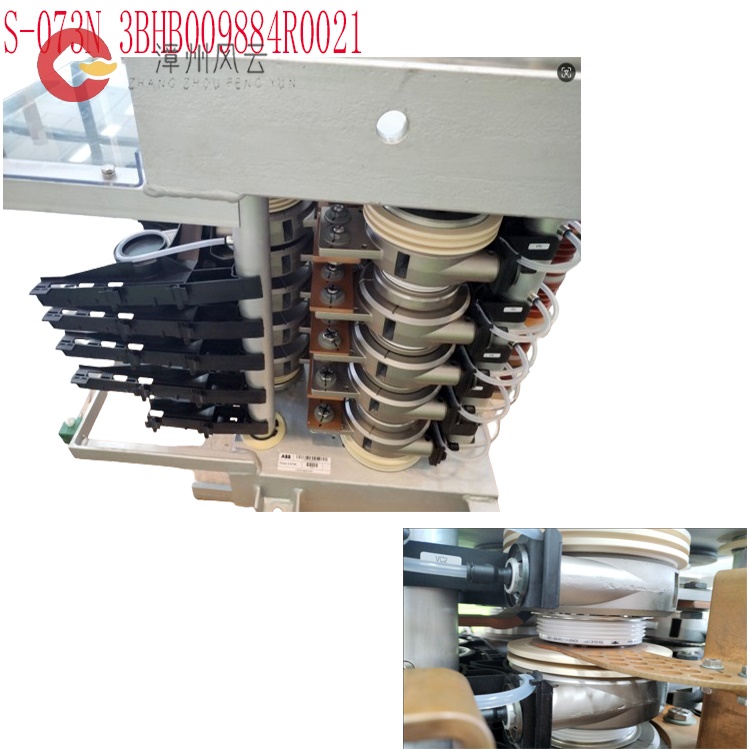

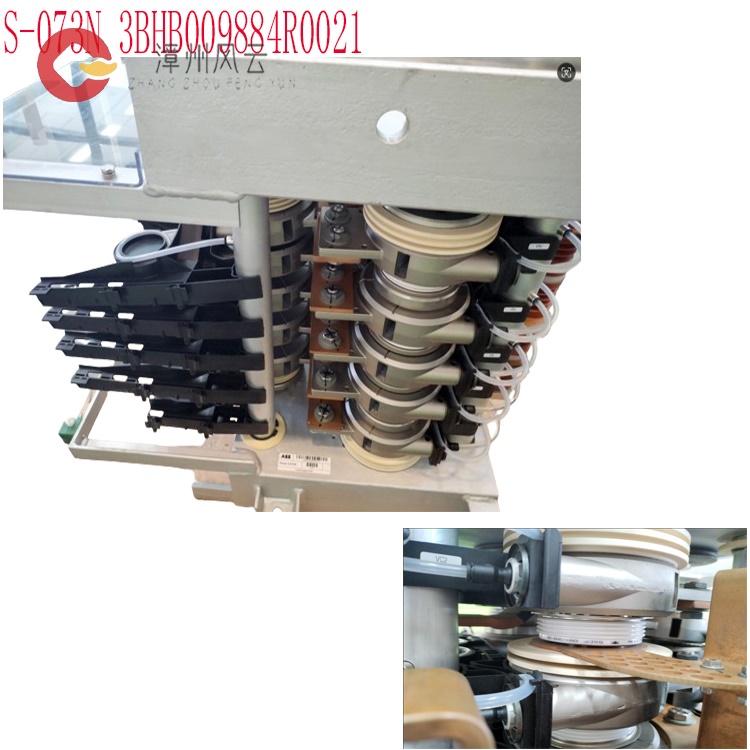

35SHY3545L0014 S-073N

3BHB009884R0021 S-073N

3BHB009885R0052 S-097H

3BHB030478R0309 S-093H

3BHB012897R0003 S-053M

S-073N 3BHB009884R0021

3BHE041430R0001 ABB

3BHE041429R0001 ABB

3BHE041418R0001 ABB

3BHE041414R0001 ABB

3BHS393721 E01 ABB

3BHS600000 E40 ABB

3BHS606571 E49 ABB

3BHS537463 E72 ABB

3BHS600000 E87 ABB

More......

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102